Basic Dry Stone Walling Principles

- kieran

- Apr 28, 2023

- 4 min read

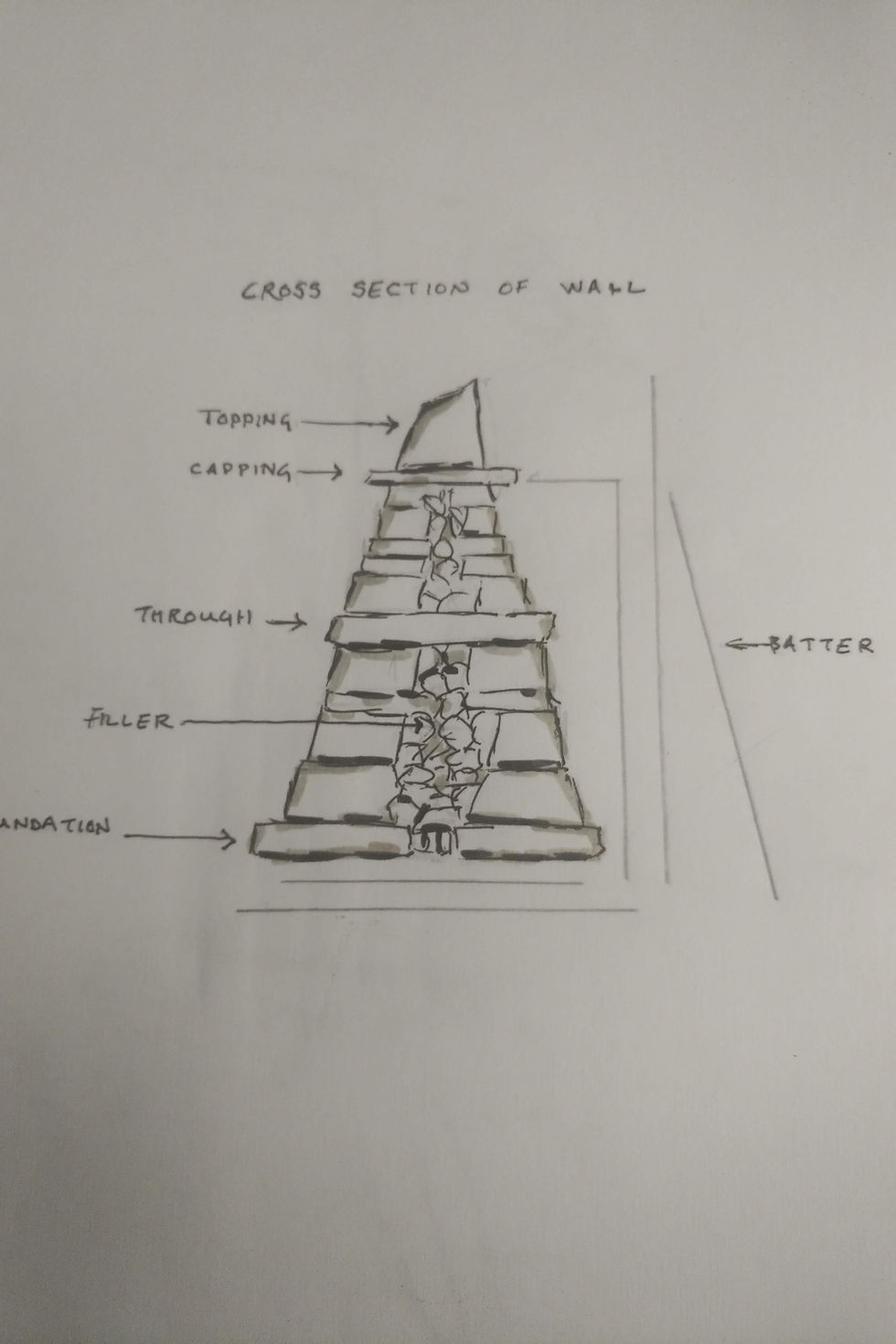

From bottom to top, here are some basic principles for dry stone walling.

The depth of foundations for a dry stone wall will depend on a variety of factors, including the height and width of the wall, the type of soil and terrain, and the local climate and weather conditions.

As a general rule, the foundation for a dry stone wall should be deep enough to provide stability and prevent the wall from shifting or settling over time. A good guideline is to excavate a trench that is at least one-third the height of the wall, although some walls may require deeper foundations for added stability.

In practice, the depth of the foundation may also depend on the local building code or regulations in your area, which may specify a minimum depth for foundations based on the height of the wall. It's always a good idea to consult with a professional dry stone waller or local building authority to determine the appropriate foundation depth for your project.

In addition to the depth of the foundation, it's also important to ensure that the foundation is level and compacted to provide a stable base for the wall. This may involve adding a layer of crushed stone or gravel to the trench and compacting it with a plate compactor or similar equipment.

The angle of the batter (or slope) on a dry stone wall is an important consideration for both the stability and the aesthetic appearance of the wall. The batter angle refers to the angle at which the wall slopes inward, or leans back, from the base to the top.

The ideal batter angle for a dry stone wall will depend on several factors, including the height and width of the wall, the type of stone being used, and the local weather and climate conditions. In general, however, a batter angle of around 5-10 degrees is common for dry stone walls.

A gentle batter angle can help to provide stability by distributing the weight of the wall evenly across the base, while also allowing for some flexibility and movement as the wall settles over time. A steeper batter angle may be appropriate for taller or wider walls, as this can help to counteract the force of gravity and prevent the wall from toppling over.

It's important to note that the batter angle may also affect the appearance of the wall, as a more pronounced batter can give the wall a more traditional or rustic look. However, this is largely a matter of personal preference and will depend on the style and context of the wall.

The thickness of a dry stone wall can vary depending on several factors, including the intended use of the wall, the type of stone being used, and the local building code or regulations in your area.

As a general rule, the thickness of a dry stone wall will depend on its height. For example, a low garden wall may only need to be 1-2 feet (30-60 cm) thick, while a larger retaining wall may need to be 3-4 feet (90-120 cm) thick or more.

In practice, the thickness of the wall may also depend on the type and size of the stones being used, as well as the particular style or design of the wall. For example, some dry stone walls may be built using large, irregular stones with smaller stones used to fill in the gaps, while others may use smaller, more uniform stones stacked tightly together.

It's important to note that the thickness of the wall will also affect its stability and durability over time. A thicker wall with a wider base will generally be more stable and less likely to shift or collapse, especially in areas with high wind or water pressure.

Dry stone walling requires a range of specialized tools that are designed to help the waller shape, trim, and fit stones together in a precise and stable manner. Here are some of the most common tools used by dry stone wallers:

Hammer: A heavy mallet or hammer is used to strike the stones and break off any unwanted edges or bumps.

Chisel: A sharp, flat-tipped chisel is used to cut or shape the stones as needed, creating a smooth, flat surface for stacking.

Pitching tool: A pitching tool is similar to a chisel but has a wider, flatter tip that is used to split or break larger stones into smaller, more manageable pieces.

String line and level: A string line and level are used to ensure that the wall is straight and level as it is being built. The string line is attached to stakes driven into the ground at either end of the wall, while the level is used to make sure that the wall is not leaning or sagging.

Shovel: A shovel is used to dig the trench for the foundation of the wall and to move soil and other debris as needed.

Wheelbarrow: A wheelbarrow is used to transport stones, soil, and other materials to and from the work site.

Safety equipment: Safety gear such as gloves, eye protection, and sturdy footwear are important for protecting the waller from injury while working with heavy stones and tools.

Crowbar: A crowbar is used to help pry or move heavy stones into place.

These are just some of the most common tools used by dry stone wallers. The specific tools needed may vary depending on the style and size of the wall, as well as the particular techniques used by the waller.

Comments